فهرست دستگاهها در این سیستم

--- دستگاه تغذیه ارتعاشی و لوکر نوع Z

--- وزنده 10/14 سر

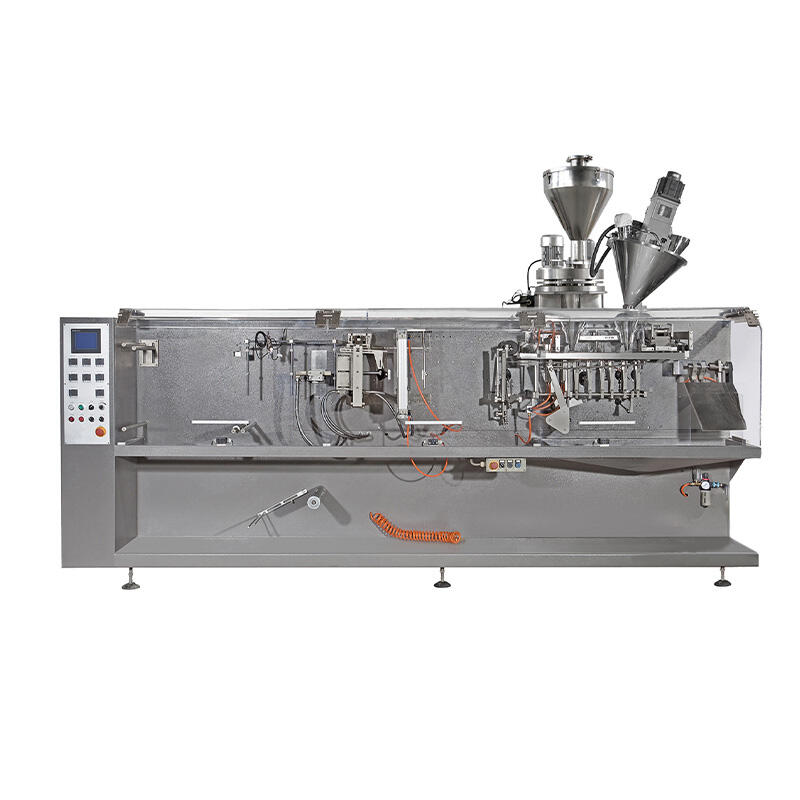

--ماشین بستهبندی اصلی

---platform

--- کانوئه محصول نهایی

II. ویژگی: این سیستم تمام فرآیندها را به طور خودکار انجام میدهد: تغذیه، دوزING، پر کردن، بستهبندی، چاپ تاریخ و منتقل کردن محصول نهایی. این دستگاه دارای مزایای وزنگیری دقیق، کارایی بالا و بدون آسیب به مواد است.

III. محدوده: این ماشین مناسب برای بستهبندی مواد جامد غیرمعمول و ذرات مانند: خوراکیهای سبزیجاتی، شیپس سیب زمینی، برنج خشک، ژلی، شکلات، شیپس سیب، دمبلی، کوکی کوچک، میوههای خشک، عدسی، دانههای سوخته، مغزوبه و ماست، مواد پزشکی، غذاهای یخ زده، و غیره است.

عملکرد اصلی و ویژگیهای قابلیتها:

1. مجهز به محافظت ایمنی، که با الزامات مدیریت ایمنی شرکت هماهنگ است.

2. از کنترلر دمای هوشمند برای دقت دمایی استفاده میکند که اطمینان از بستهبندی هنرمندانه و مرتب ایجاد میکند.

3. از سیستم PLC Servo و سیستم کنترل پnevmatیک و صفحه لمسی فوق العاده برای ترکیب مرکز کنترل رانش استفاده شده است، که دقت کنترل ماشین، قابلیت اعتماد و سطح هوشمندی آن را بهبود میبخشد.

4. این ماشین به طور خودکار تمام فرآیند بستهبندی شامل بارگذاری مواد، اندازهگیری، ساخت کیسه، چسباندن، چاپ تاریخ، تزریق هوا (یا خالی کردن) و حمل محصولات تموم شده و شمارش را انجام میدهد.

5. صفحه نمایش لمسی میتواند پارامترهای فنی انواع محصولات مختلف را ذخیره کند، بنابراین هنگام تغییر محصولات نیازی به تنظیم مجدد نیست.

6. با سیستم نشان دادن خطای، که کمک میکند تا مشکلات به طور فوری حل شوند.

7. کیسههای Pillow و کیسههای Hanging بر اساس نیازهای متفاوت مشتریان تولید میکند.

EN

EN