Automatická HFFS balicí stroj je zcela novým strojem na vytváření, dosávání, vyplňování a uzavírání pytlíků, který se skládá z výroby pytlíků, dávkování, vyplňování a uzavírání. A obalovací materiál jsou různé druhy vícevrstvých horkotěsných folií. S kombinací různých dávkovacích hlavic může stroj balit prášky, kapaliny, pasty, granuly do pytlíků s třemi nebo čtyřmi uzavřenými stranami.

Aplikace: prach a granulát: mléčný prášek, bílkovinný prášek, kávový prášek, houskový prášek, cukrová krystalka, glukóza, ají, smetanový prášek, aroma a přísada v podobě prachu a granulátu, léčiva v granulátu, talc, barvy, koření, veterinární léky, pesticidy, prašková detergenta atd.

kapaliny a pasty: rajčatová pasta, ovočná džem, šampon, kapalné hnojivo, pesticidy atd.

Charakter: Používá PLC lidské-dělení rozhraní a všechny akce jsou poháněny pneumatickým válcem. Systém pro spouštění filmu používá řízení servomotoru, takže můžeme náhodně upravovat rozměry filmu. Má výhody vysoké účinnosti, použitelnosti a stability. Balení je krásné a pevnost zapečetění je vysoká. Je to ideální volba pro balení potravin, léků, kosmetiky, pesticidů, krmiva atd.

Informace o stroji

Typ XFS-180S je horizontální automatický balicí stroj na pytlíky s kolmo stojícím dno, hlavně určený pro potravinářský, kosmetický a agrochemický průmysl. Může balit materiály jako kapaliny, prášky, granuly a různé druhy suspenzí. Tvar pytlíku je kolmo stojící pytlík, speciální tvarovaný pytlík, visací pytlík, pytlík s zipem. Používá se různé vyplňovací zařízení pro balení různých produktů.

Technický parametr

| Rozměry stroje | 6000*1100*1500(D*Š*V,mm) |

| Hmotnost | 2200kg |

| Elektrické napájení | AC380V 50Hz |

| Napájení | 8KW |

| Vzduchová dodávka | 0.5MPa |

| Spotřeba vzduchu | 200NL/min |

| Balicí kapacita | 40-60ppm |

| Šířka | 90mm-180mm |

| Velká velikost | 110mm-260mm |

| Maximální kapacita výplně | 1000ml |

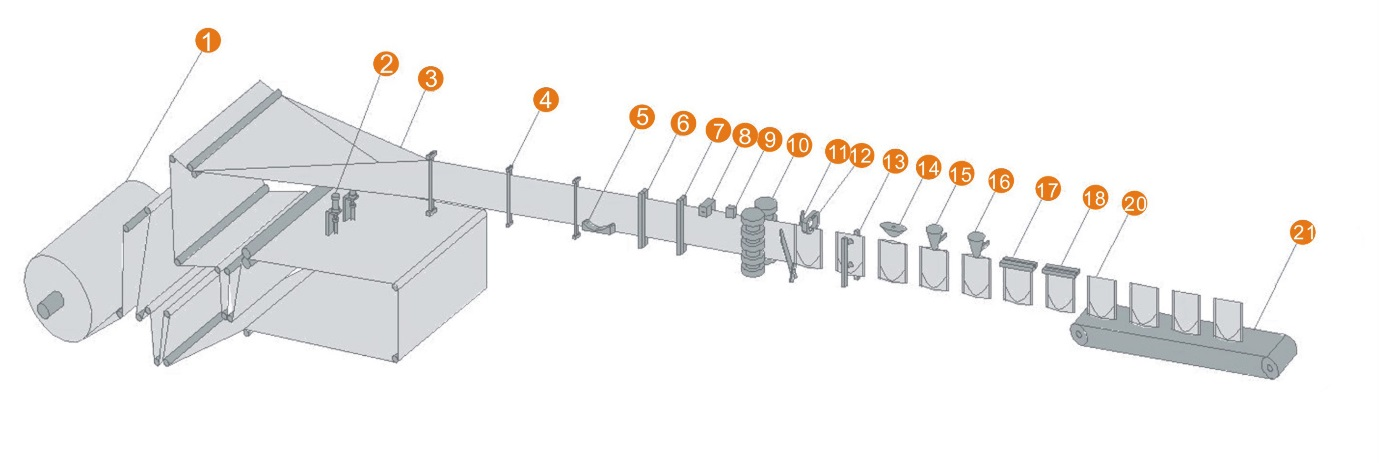

Balicí proces

| 1.vyvinutí filmu | 5.dolní uzavření | 9. trhací štěrbina | 13.otevření tašky | 17. horní uzavření1 |

| 2.probodání dolních děr | 6.svisle1 | 10.předposun serva | 14.čištění vzduchem | 18 horní uzavření2 |

| 3.tvarování pytlíku | 7.svisle2 | 11.řezání | 15.vyplňování1 | 19.dokončený produkt |

| 4.vodič filmu | 8.fotobuňka | 12.váček pro chycení | 16.nalévání2 | 20.výtok |

Horké novinky

Horké novinky2024-05-15

2024-05-15

2024-05-15

2024-05-15

2024-05-15

2024-05-15

Copyright © Shanghai Xingfei Packaging Machinery Co., Ltd. All Rights Reserved - Zásady ochrany soukromí - Blog